Water Recycling

July 26, 2022 · Dhanya

Water, A priceless gift for humanity by nature;

Life is not possible on earth without water. While three-quarters of the earth is covered in water, water scarcity is a major issue in India and other countries. Due to water scarcity, people teach us to save water and protect the environment, life and the world because of the difficulties faced by people in different areas.

Without water pollution, we need to save water for the proper supply of water for the future generation. We must stop the waste of water, reuse the recycled water properly and should maintain the quality of water. Clean water is affecting the lives of people in India and other countries of the world in many ways, and the lack of clean water is becoming a major problem.

This big problem cannot be solved by the people alone or by a group of some groups, it is a problem for which people’s efforts meet at the global level. Water-saving is becoming an important global issue as water demand increases but water supply is likely to become less yet to be paid to population growth and climate change.

Let us think about water recycling.

Why is recycling water important?

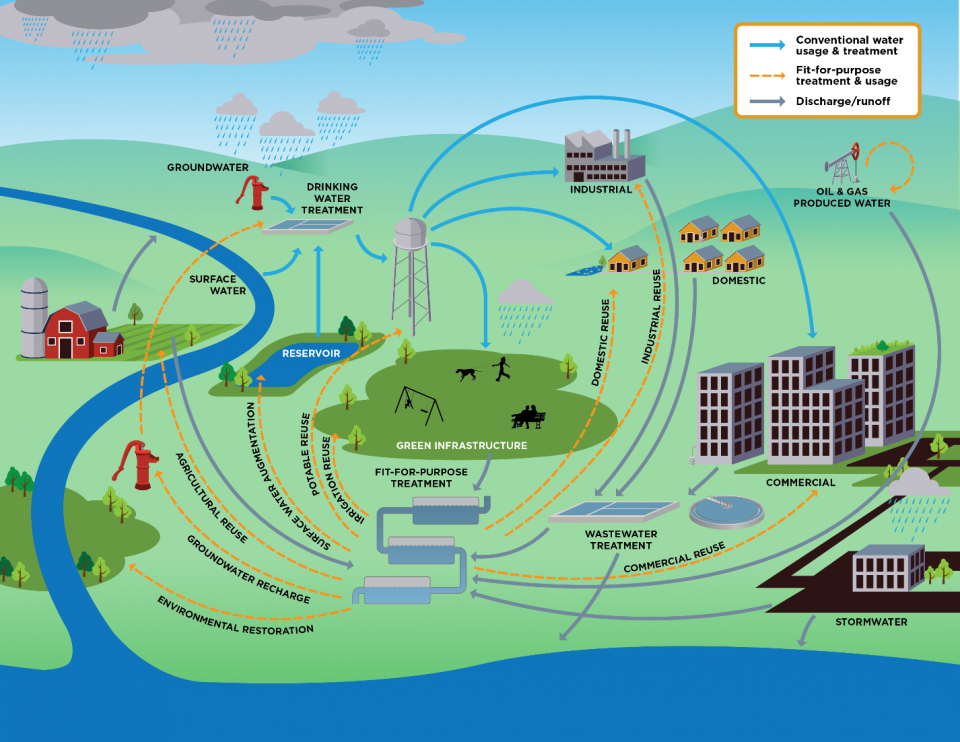

Recycling of wastewater is done to treat the wastewater to a level suitable for various purposes. Water recycling is reusing treated waste water for beneficial purposes such as agricultural and landscape irrigation, industrial processes, toilet flushing and replenishing a ground water basin and of course, drinking. The term water recycling is generally used synonymously with water reclamation and water reuse.

Necessity of wastewater recycling:

- Our population is growing at an exponential rate, water resources are dwindling, water is often polluted, and the cost of treating and distributing water has made it necessary to search for innovative water supply sources.

- The unbridled exploitation of ground water for irrigation, drinking and industrial purposes has caused the water table to recede by two meters each year.

- The over exploitation of limited resources has caused not only a perceptible decline in the waste water table but has also resulted in concentration of pollutants on ground, which otherwise would have flowed away.

- Use of highly treated sewage effluent discharge into the environment is receiving more attention as the reliable source of water.

Filter Presses are used to separate liquids from solids so that an industrial facility is able to recycle and reuse the clean filtrate again – and again – while economically disposing of the solids in the form of dry filter cakes. There are many diverse industries and applications that benefit from water and wastewater reuse and these include mining and mineral processing, the power industry, fine coal dewatering, aggregates, lime, granite, frac sand, commercial laundries, plating, breweries, and other industries that may be generators of hazardous waste. Many industries have made water/wastewater recycle and reuse a top priority for the many advantages it offers in terms of time, money, resources, and protecting our environment.

Is recycled water safe?

Yes!! Recycled water is safe for human contact but it is not intended for drinking. Recycled water has been use extensively throughout the U.S.A. including for food crops, over ground water aquifers and in recreational lakes for the past 40 years with no negative health impact.

Wastewater recycling can be done in number of ways depending on:

- The characteristics of wastewater.

- Surrounding environmental conditions.

- Its usage after recycling.

- Quantity required being recycled.

- Available sources for recycling of wastewater.

- If economically viable.

Different Techniques of wastewater recycling:

1. Conventional techniques:

- Disinfection

- Oxidation

- Chemical dosing for water quality correction.

- Filtration

- Softening

- Activated carbon Treatment

- Anion/Cation exchange

- Reverse osmosis.

2. Non-conventional techniques: A) Natural wetlands. B) Constructed wetlands.

Industrial uses of water

Manufacturing and other industries use water during the production process for either creating their products or cooling equipment used in creating their products. According to the United States Geological Survey (USGS), industrial water is used for fabricating, processing, washing, diluting, cooling, or transporting a product.

Industrial water and wastewater is a by-product of industrial or commercial activities. Whether it's the food we eat or the products we consume, water is required for nearly every step of production across a multitude of different industries. The resulting wastewater must be carefully managed.

Industries that have a high usage of water and need for treatment include: brewery and carbonated beverage water; dairy industries; sugar mills and refineries; textile manufacturing; pulp and paper mills; oil and gas; the automotive and aircraft industries and many others.

Here are just 5 advantages that recycle and reuse of process water and wastewater can bring to your company and to our communities:

1. Reducing environmental impact

Filter presses dewater and separate liquids and solids in a broad range of industries, many of which are actively developing and implementing strategies for water conservation and water and wastewater reuse. Using advanced, large-scale filter press technology, mining and mineral processing companies can innovatively deal with mine tailings, dry-stacking them, rather than using tailings ponds. Tailings ponds have the potential for various environmental risks such as leaks of contaminants into surface and ground waters used for drinking, wildlife exposure, and consequences to aquatic communities.

2. Reduce demands and stress on freshwater supply

Agriculture is a major user of water. Using recycled, treated wastewater can relieve the stress on freshwater supplies used for agricultural purposes such as for irrigating crops, commercial and residential landscaping, irrigating public and private golf courses, and for nurseries and horticulture. Treated and recycled wastewater provides a cost-efficient supply that decreases the demands – and stress – on freshwater sources such as groundwater, rivers, and reservoirs. This is particularly important in areas that have been affected by water scarcity and drought.

3. Eliminating the need to transport water

Rather than a disposal liability, recycling and reusing industrial wastewater onsite is now considered a smart business practice, one that helps companies become more profitable and efficient. The transport of wastewater to offsite facilities is very expensive. When industrial facilities recycle wastewater on-site for reuse in a variety of industrial processes, they are saving substantially on transportation, disposal and energy costs. Recycling and reusing wastewater is an economical path to meeting your industry’s large-scale water demands because, let’s face it, many, many industries are extremely water-intensive.

4. Improving sustainability

Dewatering of sludge – the separation of the liquid and solid components that make up the sludge waste – is an inherently sustainable, environmentally-friendly technology. It allows both for water reuse and for the cost-effective disposal of the dry cake containing a high degree of solids – which cannot be reused – and which may be hazardous to the environment & future generations, if not handled responsibly.

5. Avoiding expensive non-compliance fees

Doing good for the environment by minimizing pollution is a major benefit of using filtration technologies that help with wastewater reuse and recycle. In addition, implementing wastewater reuse strategies makes it easier for you to avoid costly fees associated with non-compliance with stringent wastewater discharge regulations. Being an environmentally-conscious company goes hand-in-hand with profitability.

Quick Enquiry

To know more about Associated Chemicals feel free to send a message

Our Sister Concerns

Our Sister Concerns

Usefull Links

Get In Touch

Assochem Chambers, Bypass, Edapally,

Kochi-682024, Kerala, India.

Phones : +91 9495999349, +91 9388610189, +91 484 2339190, +91 484 2348028

E-mail : nsn@assochem.in, marketing@assochem.in, mail@assochem.in

Support