SPECIALTY NATURAL RUBBER LATEX

September 30, 2024 · JOSEPH JOHN

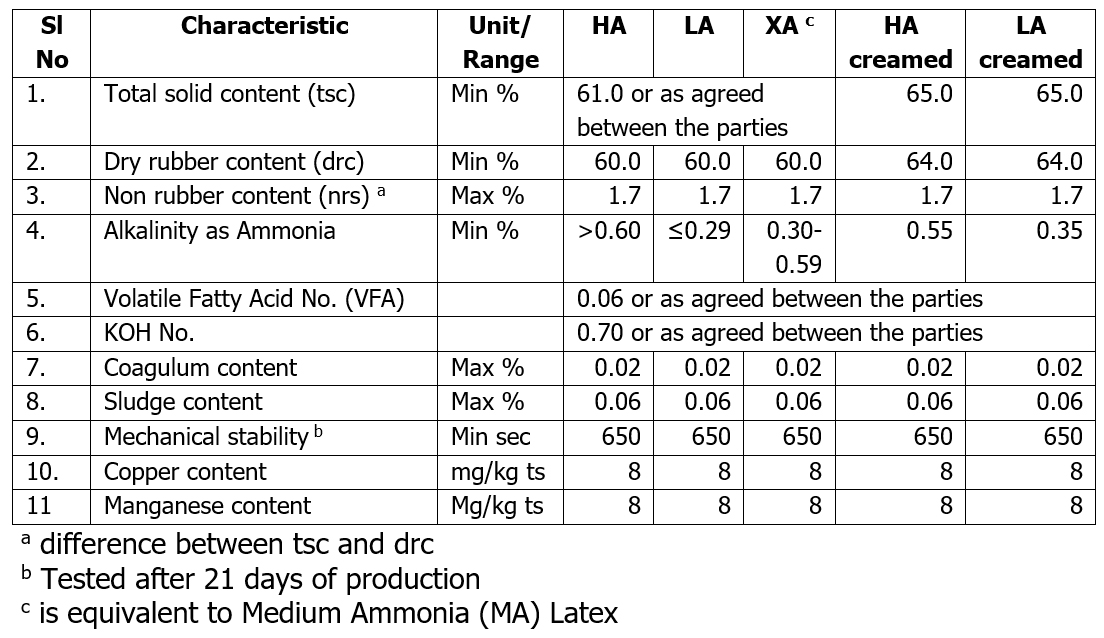

Specialty Natural Rubber Latices cover an expanding group of latices that are variants from the conventional grades of natural rubber latices as given in ISO 2004:2017. Natural rubber latex concentrate grades containing ammonia and/or other preservatives, which has been subjected to some process of concentration is classified as:

- Type HA natural rubber latex concentrate (High Ammonia)

- Type LA natural rubber latex concentrate (Low Ammonia)

- Type XA natural rubber latex concentrate (Medium Ammonia)

- Creamed type HA natural rubber latex concentrate (HA Creamed)

- Creamed type LA natural rubber latex concentrate (LA Creamed)

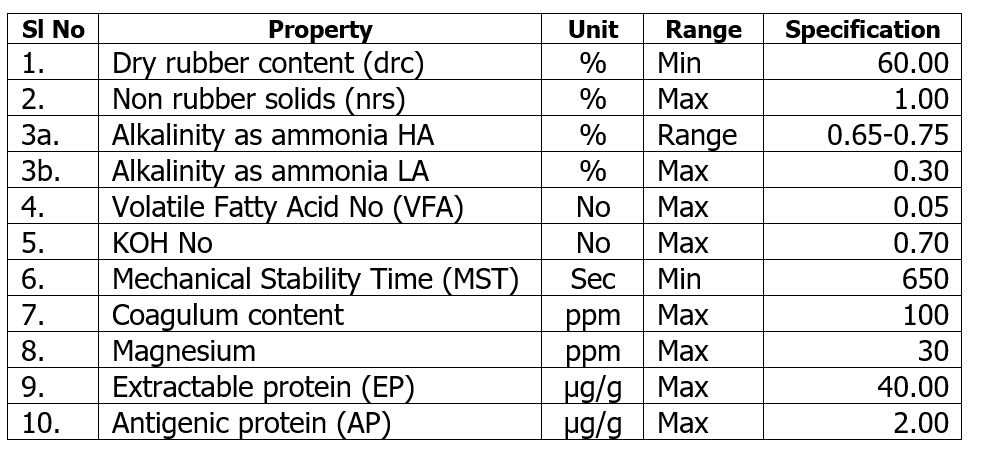

The requirements for these grades as per ISO 2004:2017 are

The Speciality Latices considered in this article are:

- Nitrosamine Free Latices

- Ultra Low Protein Latex

- Ultra Low Ammonia Latex

- No Ammonia Latex

The Base Material – Natural Rubber latex

Natural Rubber is obtained from the tree botanically called Hevea brasiliensis. It is known for its lactiferous system from which latex is extracted by tapping the trunk. Latex is produced in the latex vessels situated in the bark of the tree. The latex is extracted by controlled wounding of the tree which is called tapping. During tapping the bark of the tree is cut together with the latex vessels to facilitate flow of latex.

A number of regulations have necessitated the need for specifying the geo coordinates of the plantation source, restriction in the use of Nitrosamine generating chemicals, restricting the amount of Proteins in latex, restrictions in the use of volatile organic compounds (VOC) like ammonia, restrictions in the use of Biocides etc.

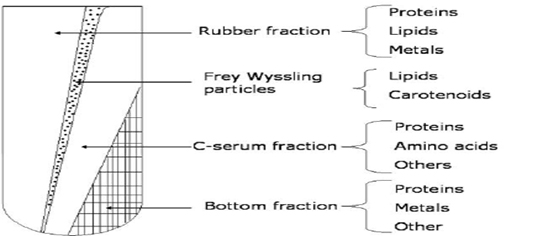

Natural Rubber obtained from the rubber tree is in the form of liquid rubber and is a colloidal suspension of rubber particles in an aqueous medium and is called Field Latex. Field latex contains approximately 30% dry rubber and non-rubber solids like proteins, carbohydrates, amino acids, organic acids, metal ions etc. The composition of field latex varies with the variety (clone) of the rubber tree, the geo location and the season. Laboratory centrifuging of latex can give you the following fractions.

The rubber particles in field latex is covered with protein imparting a negative charge to it. The negative charge keeps the particles apart (repulsion of like charge) and prevents the coalescence of the particles which would lead to coagulation (solidifying) of the rubber. The presence of bacteria in the latex leads to coagulation of the field latex. The bacteria feeds on the carbohydrates and sugar and releases organic acids (Volatile Fatty Acids VFA) which neutralizes the negative charge of the rubber particles and this leads to coagulation. The bacterial multiplication is in geometric progression hence the need for its control.

It is hence necessary to supplement the negative charge of the rubber particle by the addition of a preservative like ammonia which can impart the negative charge. The level of Ammonia in field latex has to be more than 0.35% w/w as any level below this will create a suitable pH for the bacteria present in latex to multiply. It is also necessary to use a chemical combination like Zinc Oxide (ZnO) and Tetra Methyl Thiuram Disulphide (TMTD) which act as a biocide and prevents the multiplication of bacteria.

This is the conventional method of preservation of field latex and is now restricted by a number of new regulations and legislations in Europe, USA etc Natural Rubber latex contains proteins and its presence is restricted especially in Europe and USA due to the issue of protein allergy. Many customers prefer the latex with a low level of protein content.

Concentration of Field Latex

Field latex is converted to dry rubber forms like Rubber Smoked Sheets (RSS), Pale Latex Crepe (PLC), Technically Specified Rubber (TSR) etc for solid products like tire, belts bushes etc. For dipped, foamed and cast products like condoms, gloves, catheters, foam etc rubber is required in the liquid form. Since the processability of field latex is poor, cost of transport high and deterioration of quality fast. It is concentrated to 60% dry rubber content mainly by the process of centrifuging. This reduces the water content and also the non-rubbers.

The three grades of Centrifuged Latex (CL 60) being

- HA CL 60

- MA CL 60

- LA CL 60

HA CL 60 has an ammonia content of 0.65% to 0.75% whereas the LA CL 60 has an ammonia content of below 0.30%. In the case of LA CL 60 the preservation is supported by using the bactericide ZnO/TMTD. This bactericide has come in for restrictions. The grades that generally move in the market are HA and LA. A number of other improved grades are now being produced and available.

Improved Preservation Methods and Grades

The improved preservation methods and grades are

- TMTD free preservation system

- Ultra low ammonia preservation system

- Ammonia free preservation system

- Deproteinised CL 60

Source of Latex

The European Union Deforestation Regulation (EUDR) establishes strict measures to prevent companies from placing products on the EU that are linked to deforestation or forest degradation. It will also be illegal to export such products from the EU.

Operators and large traders will need to demonstrate origin, including geo coordinates in an auditable manner, to prove the product is deforestation free.

December 31 2024, marks the day by which supply chain stakeholders, including producers, importers, manufacturers, brands, and retailers within the European Union must ensure they are selling, importing and exporting EUDR compliant rubber or rubber products.

The term "deforestation-free" means that relevant products and their raw materials are sourced from areas not affected by deforestation or forest degradation after December 31, 2020.

The information to be registered includes geolocation information which is the data that shows the exact location and size of the areas where the rubber is grown and harvested.

Small-scale producers who don’t directly engage in selling their products within the EU market are not subject to this Regulation, as they are not classified as operators or traders. For goods originating from outside the EU, the responsibility mainly lies with the business introducing these products to the EU market. This business must ensure and verify that the precisely mapped and geographically identified area aligns with the actual location where the products were cultivated or manufactured.

Preservation of Field Latex

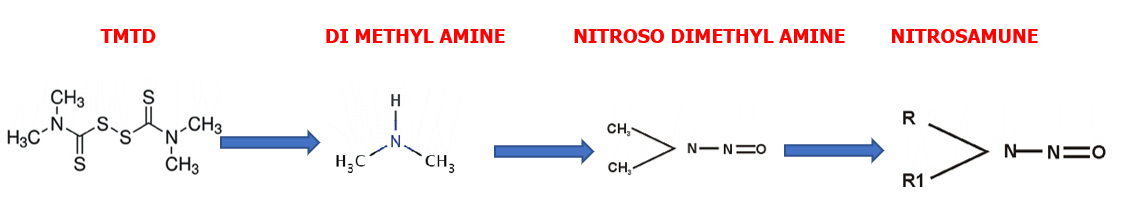

The generally used Ammonia plus ZnO/TMTD system of preservation of field latex has come in for restrictions due to the carcinogenic character of TMTD. TMTD gets converted to Nitrosamines. Nitrosamines or more formally N-Nitrosamines are organic compounds featuring a nitroso group bonded to a deprotonated amine. Nitroso Compounds are the most wide acting group of carcinogen known, and among the most potent. It is also reported to create endocrine problems. The formation of Nitrosamines is generally possible when secondary or tertiary amines react with in situ nitrous acid.

For the preservation of field latex as Low Ammonia Grade (LA) the conventional preservative system is

Ammonia - 0.35% w/w

ZnO+TMTD 50% - 100 g per 100 kg field latex

It has now become necessary that TMTD be replaced by least potent higher molecular weight accelerators like TBzTD, Zinc diisononyldithiocarbamate (Arbestab Z) etc. These accelerators are costlier than TMTD hence many processors are hesitant to use them. It is a social responsibility for the processers to replace TMTD and the manufacturers to compensate the cost difference.

High Ammonia (HA) field latex preservation does not use a bactericidal agent like ZnO+TMTD but ammonia is used is larger dosages. The field preservation is usually done at 0.50% w/w ammonia and in the factory, it is stepped up to 0.80% w/w. For delayed processing it is further stepped up to 1.20% w/w. This high level of ammonia creates a suffocating situation within the factory hence is not preferred by many processers. Further the use of a bactericidal agent gives better control on the quality especially the Volatile Fatty Acid No (VFA No).

No ammonia preservation systems have been developed (NAFL0612/NACL0312) and in use for quite some time now. It consists of a combination of Amino Alcohols, Chelating agents, Biocide and Surface-active agents. The recommended dose of NAFL0612 is 3.40 kg per 100 kg field latex. Field Latex so preserved can be processed into No Ammonia Centrifuged Latex/Ammonia Free Centrifuged Latex (NACL 60 or AFCL60). The properties and stability of No Ammonia CL 60 is found to be good. This product finds application in areas like body paint, adhesives etc.

Pre-Processing Operation for Centrifuging

The preprocessing operation varies with the final grade of CL 60

- High Ammonia CL 60 (HA)

For processing into HA CL 60 the field latex is bulked and tested for dry rubber content (drc), total solids (tsc), Ammonia, Volatile Fatty Acid No (VFA No.) and Magnesium Content. Ammonia is stepped up to 0.80% w/w if no LA preservatives have been used in field latex and to 0.35% w/w if LA preservatives have been used. Magnesium is then precipitated by complexing with Phosphate ions and allowing to settle.

Based on the concentration of Mg2+ sufficient DAHP is added as a 20% solution. The procedure involves the estimation of Mg++ present in field latex and addition of calculated amount of DAHP and stirring for 30 minutes. The treated field latex is then left undisturbed for 24 hours. The Magnesium Ammonium Phosphate complex formed settles to the bottom of the tank. The rate of settling is estimated as 1.60 m per 8 hours. If the reception/desludging tank height is more than 1.50 m, more time has to be given for the complex (sludge) to settle and harden at the bottom.

Once the sludge settles the field latex is withdrawn by syphoning or pumping from the top without disturbing the sludge.

There is a practice to have 2 outlets for the tank – one at the base and the other 25 to 30 cm above that. The desludged latex is fed into the machine from the top outlet. This is done to save on the transfer. Here the caution should be that the tank has sufficient slope and the output valve should be 35 to 50 cm dia only. If a bigger dia valve is used the velocity of discharge can disturb the sludge and take it into the machine whereby the purpose of desludging is lost. The other issue is that if a small dia valve is used, sufficient latex will not be got to feed all machines.

- Low Ammonia CL 60 (LA)

For processing into LA CL60 the field latex will naturally be preserved as low ammonia. In this case the latex is tested and bulked as for HA and ammonia maintained at 0.35% w/w. Desludging is done as above and centrifuged.

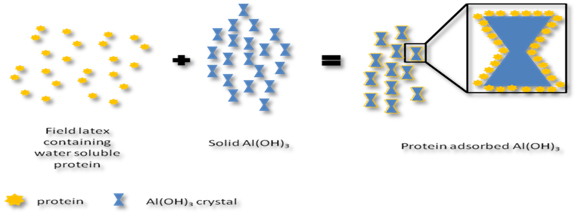

Ultra Low Protein CL 60 (ULP CL60)

This process of deproteinizing described is a multi-patented process licensed to Vystar Corporation USA The main ingredient of the deprotenising dispersion is special grade of Aluminum Hydroxide. It also contains ingredients that can split the protein chain. Aluminum Hydroxide by its nature adsorb the proteins on to the surface

For the processing of field latex into Ultra Low Protein CL 60 by the Vystar patented process, latex is tested and bulked as in HA or LA. The patented dispersion code named VYULP0303 100 is used for the deproteinization.

1.65 kg of the dry dispersion is used for every 1000 kg of field latex. 1.65 kg of the dispersion VYULP0303 100 is mixed with 1.35 kg of 10% Ammonium laurate and made into a paste. This 3 kg is mixed with 27 kg of 5% Ammonia solution and added for every 1000 kg field latex.

The dispersion mix is added slowly with stirring and the latex stirred for 24 hours at a low rpm of 30 to 50. After 24 hours stirring the required DAHP is added and desludging done as in the case of HA and LA. The latex is finally centrifuged using ideal feed rate and skim discharge screws, to get Ultra Low Protein CL 60.

- No Ammonia CL 60

Field Latex preserved using NAFL0612 is tested and bulked as in the case of HA/LA (No Ammonia is added). Desludging is done as usual followed by centrifuging. Due to the absence of Ammonia the precipitation of Mg++ takes more time hence more setelling time has to be given.

Grades of Centrifuged Latex

The various grades of Centrifuged Latex are

- High Ammonia (HA)

- Low Ammonia (LA)

- No Ammonia/Ammonia Free (NA/AF)

- Ultra Low Protein (ULPL)

- High Ammonia CL 60

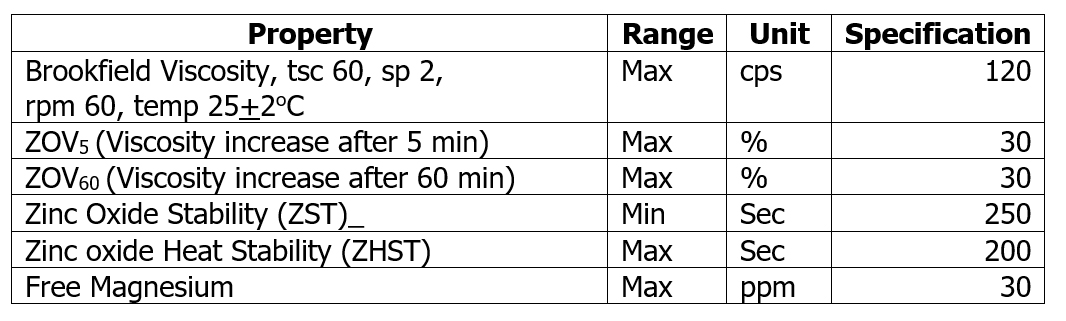

Field Latex concentrated to 60% drc by centrifuging is tested and standardised for drc and alkalinity as ammonia and other critical parameters as given in the initial table.

The additional Chemical Stability and critical parameters usually requested by manufacturers are

- Low Ammonia CL 60

The process of centrifuging to Low Ammonia CL 60 is same as that of High Ammonia CL 60 except that the preservation system is different. The ammonia level is maintained at below 0.30% and a secondary preservative cum biocide is added. The conventional secondary preservative used is a 1:1 combination of ZnO+TMTD as a 50% dispersion and at 50g per 100 kg of centrifuged latex.

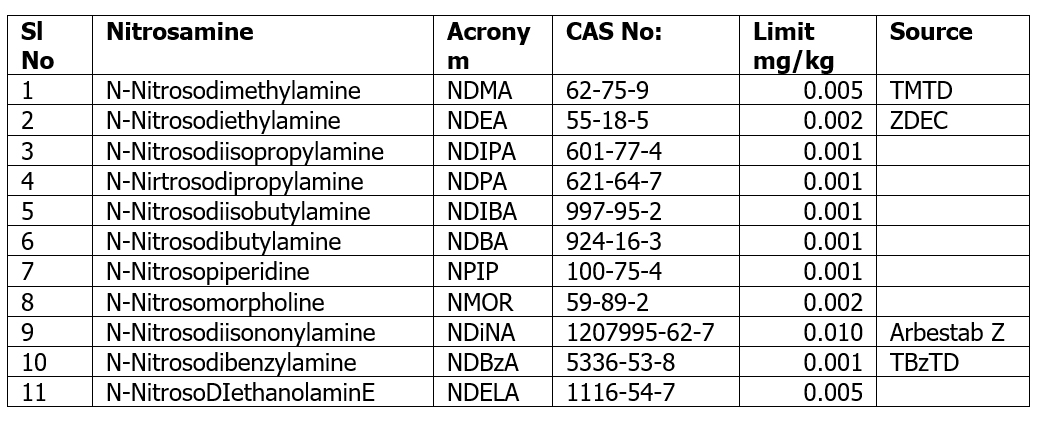

TMTD and similar accelerators generate Nitrosamines. The presence of such accelerators can reflect as Nitrosamines in the final product. The range of nitrosamines, its limits etc are as under.

The specification for N-Nitrosamines and N-Nitrosatables are as under

Toys (including balloons)

N-Nitrosamine 0.05 mg/kg. N- Nitrosatables 1.00 mg/kgTeats

N-Nitrosamine 0.01 mg/kg. N- Nitrosatables 0.10 mg/kgFor lesser Nitrosamine formation higher molecular weight accelerators replace TMTD. Caution has to be taken to control the dose, as otherwise the residue will pass on to the product also.

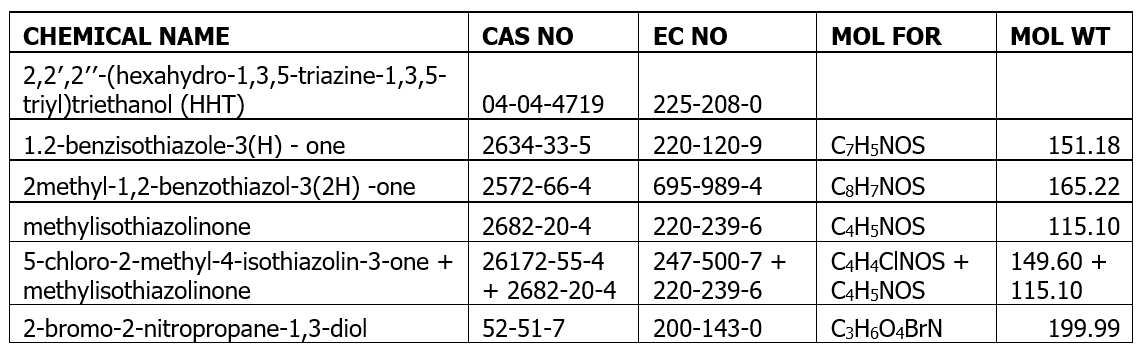

Biocides are used by many processors. The use of biocide is also restricted by regulation EU 528/2012. Only biocides approved in list PT06 can be used. The usual dose is 0.15% to 0.20% w/w of 20% biocide. The list includes

- No Ammonia/Ammonia Free CL 60

As noted above, for the production of Ammonia Free CL60; right from field preservation a NO Ammonia preservative is used. It is also to be noted that the preservative should be low nitrosamine generating for the product to be ecofriendly and accepted in EU and similar countries. Pre processing operations is done as in the case of HA CL60 and centrifuged as usual.

The centrifuged latex is preserved using a combination of Amino phenol, chelating agent, Surfactant and permitted biocide. The preservative is available (NACL0312) and the dose is 1.10 kg/100 kg w/w. Being No Ammonia CL60 it will be noticed that the Mechanical Stability develop only very slowly, hence a level of 0.05% Lauric Acid converted to Potassium Laurate will have to be added.

No Ammonia CL60 shows good stability and good processability. There is an adaption for No Ammonia CL60 where the field latex is preserved as Low Ammonia and centrifuged. The final Ammonia of CL60 will be around 0.15% w/w. This latex is preserved using NACL0312 at 1.10 kg per 100 kg CL60. This CL60 with ammonia at 0.15% is called Ultra Low Ammonia CL60. This adaptation is less costly than No Ammonia CL 60.

- Ultra low Ammonia CL 60

Deproteinisation of field latex by the Vystar process consists of a combination of splitting long chain proteins, adsorption on to the Aluminium Hydroxide content of the dispersion, removal by settling of the sludge complexed with the phosphate ions and by throughput by appropriate feed pipe and skim screw while centrifuging.

Both the Extractable and Antigenic proteins are targeted unlike the removal of only the Extractable Proteins during the leaching process of the product. The deproteinised field latex is centrifuged as usual. The practice is to monitor the MST for 10 days after centrifuging and adjustment of Ammonia. If an MST of above 450 sec is achieved by the 10th day, no laurate soap is added.

The targeted parameters of ULPL CL 60 is

Latex Rubber Products

The important rubber products from Natural Rubber Latex can be classified as

- Dipped products

- Cast products

- Foam products

An alternate classification can be

- Body contact products

- Food grade products

- Non-contact products

The restriction to non-ecofriendly components and additives varies mainly with the use of the product, namely a teat will have a stricter specification than a balloon or a glove.

The latex foam will have a more relaxed specification. The important controls are on the Protein, both Extractable and Antigenic, the presence of Nitrosamine creating accelerators.The manufacturing factory will prefer a latex with lower ammonia content.

Conclusion

The latex processors have a duty to use only safe chemicals during the production of Centrifuged Latex (CL60) and the manufacturers have the obligation to use only safe chemical combinations during the manufacturing process.

Both the processers and manufacturers have to work together with the processors being compensated for the additional cost by the manufacturers and the manufacturers getting a fair price for their product. Let us join hands to make the world a better place to live for us and our children.

Quick Enquiry

To know more about Associated Chemicals feel free to send a message

Our Sister Concerns

Our Sister Concerns

Usefull Links

Get In Touch

Assochem Chambers, Bypass, Edapally,

Kochi-682024, Kerala, India.

Phones : +91 9495999349, +91 9388610189, +91 484 2339190, +91 484 2348028

E-mail : nsn@assochem.in, marketing@assochem.in, mail@assochem.in

Support