THE BEST ELASTOMER “NATURAL RUBBER”

GIFT OF NATURE

June 23, 2022 · Neethu

Discovery of wild rubber

The credit of observing an application of rubber can be given to Christopher Columbus and those who accompanied him during his voyage to the Carrebian, where they observed the inhabitants playing with rubber like balls.

The credit of observing an application of rubber can be given to Christopher Columbus and those who accompanied him during his voyage to the Carrebian, where they observed the inhabitants playing with rubber like balls.

In his second voyage 1493- 1496, he witnessed a game played by inhabitants of Haiti (Haiti, is a country located on the island of Hispanoila to the east Cuba and south of The Bahama.) It is surprising that there is no tree or shrub that produces rubber indigenous to Haiti.

The name rubber

A major breakthrough occurred in 1770, when chemist Joseph Priestley noticed that lines drawn with a pencil can be removed using rubber. That is how the name ‘rubber’ – derived from the English verb ‘to rub out’ – came to be used.

A major breakthrough occurred in 1770, when chemist Joseph Priestley noticed that lines drawn with a pencil can be removed using rubber. That is how the name ‘rubber’ – derived from the English verb ‘to rub out’ – came to be used.

Hevea brasiliens is a forest tree which is indigenous to the tropical rain forests of Central and South America and the only major commercial source of natural rubber is one of the highly domesticated crops in the world.

Natural Rubber Producing Countries

- The major Natural Rubber Producing Countries are Bangladesh, Cambodia, China, India, Indonesia, Malaysia, Papua New Guinea, Philippines, Singapore, Sri Lanka, Thailand and Vietnam.

- Several plant species produce Natural rubber.

- In certain types of plants latex is obtained by specific wounding techniques while in others extraction is done by chemical and physical means.

- Hevea brasiliensis is the most important source of NR

- Other rubber bearing plants are of minor importance with respect to quantity, quality, method of latex collection, cost aspects etc. In many species rubber content is too low to consider it as a source of natural rubber.

- Different plant sources of NR:

| Species | Popular name |

|---|---|

| Heveabrasiliensis | Para rubber |

| Partheniumargentatum | Guayule rubber |

| Manihotglaziovii | Ceara rubber |

| FicusElastica | India rubber |

| Castilla elastic | Panama rubber |

- Natural rubber is polyisoprene in which monomer units are of isoprene i,e 2-methyl-1,3 butadiene.

Latex

|

Appearance of NR:

|

European language: “lait”= milk

Latex is originally defined as the stable dispersion of natural rubber particles in aqueous medium as produced in the rubber tree.

Latex is a milky white dispersion of rubber in water and field coagulum is the auto coagulated latex on the tapping panel (tree lace) and the collection cups (shell scrap and cup lumps). Both the latex and field coagulum harvested from rubber plantations being highly susceptible to degradation by contamination on keeping, have to be processed into marketable forms that will allow safe storage and marketing.

The latex harvested is called field latex and subjected to preservation and concentration for commercial rubber product manufacture use.

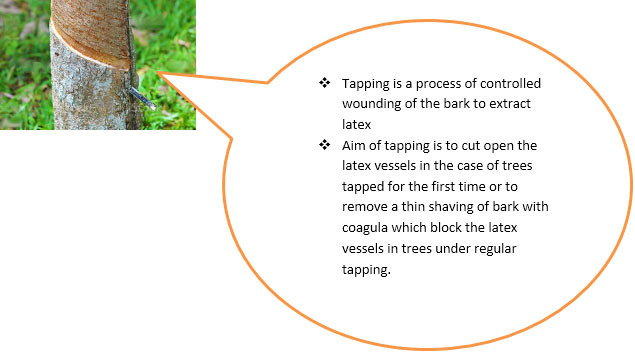

Tapping

Tapping is done during the early hours of the day because turger pressure is very high at that time

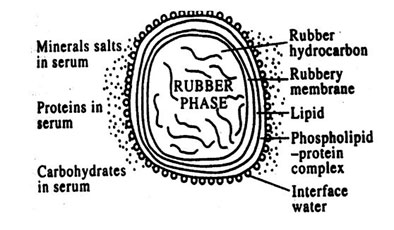

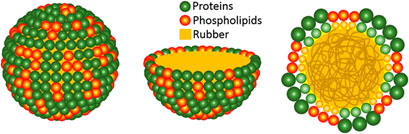

Schematic representation of a rubber particle:

Marketable forms of rubber

- Sheet

- Ribbed Smoked Sheet (RSS)

- Air Dried Sheet (ADS)

- Crepe

- PFL and Latex concentrate

- Block rubber

Sheet, Crepe and Latex Concentrate are in the dry form and almost 90% of the total NR produced in the world are at present marketed in these 3 forms. In the international market, these 3 broad types of dry NR, are available as over 40 grades consisting of ribbed smoked sheets and air dried sheets, crepes, which includes latex based and field coagulam derived estate brown crepes, remilled crepes etc. and Technically Specified Rubber in block form.

Need for preservation of latex (Need for maintenance of good quality of rubber)

About 80 % of the crop is as latex and 20% as field coagulum. These different forms of crop are highly susceptible to bacterial contamination on keeping due to which chemical change occurs shortly after the latex leaves the tree.

- Latex coagulates within a few hours - spontaneous coagulation.

- Partially coagulated latex and latex coagulum develops fowl smell- putrefaction.

Anticoagulants

Chemicals added to latex to prevent precoagulation

1. Sodium sulphite

Commercially available as a white powder, 90 to 98 % pure

Used as 0.05 % by volume

5 g of the chemical in 100 ml water is sufficient for 10 L field latex

2. Ammonia

As liquified gas in cylinders or as 20 % solution in water

Used as 0.01 % by volume

5 ml of the solution in 100 ml water is sufficient for 10 L field latex

3. Formalin

Approximately 40 % solution of formaldehyde in water

Used as 0.02 % by volume

5 ml of formalin in 100 ml water is sufficient for 10 L field latex

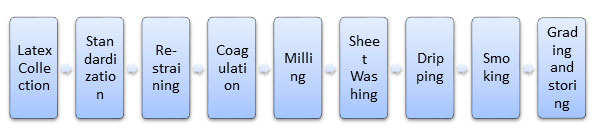

PREPARATION OF RIBBED SMOKED SHEET [RSS]

Natural rubber latex is traditionally converted into sheet form through careful coagulation and subsequent milling process on two roll mills.

Quick Enquiry

To know more about Associated Chemicals feel free to send a message

Our Sister Concerns

Our Sister Concerns

Usefull Links

Get In Touch

Assochem Chambers, Bypass, Edapally,

Kochi-682024, Kerala, India.

Phones : +91 9495999349, +91 9388610189, +91 484 2339190, +91 484 2348028

E-mail : nsn@assochem.in, marketing@assochem.in, mail@assochem.in

Support