EXTRUDED RUBBER PRODUCTS

January 24, 2023 · Neethu Parameswaran Namboodiri

What is Extrusion?

Rubber extrusion is a process used to manufacture extruded rubber products. In this process uncured/ un-vulcanized rubber is passed through an extrusion machine to force synthetic or natural rubber material through a shaped die under high pressure. After passing the uncured rubber through the extruder it generates profiles having a fixed cross-sectional area as it passes the die. By changing the die we can manufacture products according to our specifications.

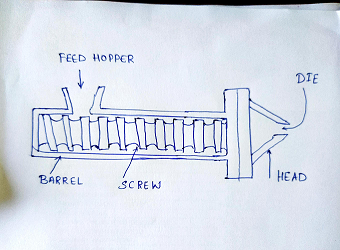

The rubber extruder has two main parts: a heated shearing screw conveyor and a die.

The word “Extrusion” means to “Thrust Out” or to expel.

Extruders are machines which shape rubber to a profiled strip by forcing it through a die.

In the simplest form an extruder consists of four basic components :

- A Drive System

- A Barrel

- A Ram or screw for forcing the rubber through the barrel

- A head holding the die which ultimately gives the desired shape.

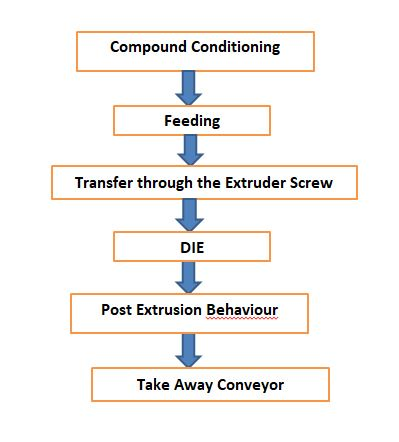

RUBBER EXTRUSION AS SERIES OF UNIT OPERATION –

- Role of the Screw: To feed the Die with homogeneous material with appropriate temperature and pressure.

- A rubber extruder is a Screw pump connected to a Die. Generally short control parameters are : Temperature Profile along the barrel, The Thermal Control of the Screw, Screw rotational Speed.

- Output depends on ( for a given set of conditions) : Viscoelastic Properties of the compound, The Temperature and the pressure conditions at the entrance of the Die and the Die Geometry (including the Entrance Region)

- Post Extrusion Behaviour: An Elastic Phenomenon (Die Swell) The extrudate, just after leaving the Die assumes dimensions which are different from those of the orifice (Die). This phenomenon is known as Die swell and is caused by stress relaxation.Check out the best EPDM rubber products manufacturer in Kerala.

Designing of Extrusion Die

- Die swell has to be accounted

- Thicker portion of the extrudate thinner than required. Thinner portion of extrudate thicker than required.

- Restriction of flow towards larger opening either by baffles or by proper tapering.

- Dead spots to be avoided at all costs. By proper taper all rubber should be channelled towards Die opening. If dead spots cannot be avoided than bleeder holes at the dead spots.

- Longer land width, better finish.

Associated Rubber Chemicals Kochi Pvt Ltd are manufacturers of Extruded rubber products.

Some Products we offer

- EPDM Rubber Hose ( Any variants )

- EPDM Protectors

- EPDM Cord

- EPDM Rubber Beadings ( For UPVC Aluminum Fabricators - Windows and doors, Container Beadings, Bus Building, mosquito nets, etc)

Advantages of our Extruded Products

- Flexible, Long Lasting & Durable.

- Made from high quality EPDM.

- Will not get harden by time.

- Customisable

- Capable of withstanding various conditions like vibration, climate & aerodynamic effects

Quick Enquiry

To know more about Associated Chemicals feel free to send a message

Our Sister Concerns

Our Sister Concerns

Usefull Links

Get In Touch

Assochem Chambers, Bypass, Edapally,

Kochi-682024, Kerala, India.

Phones : +91 9495999349, +91 9388610189, +91 484 2339190, +91 484 2348028

E-mail : nsn@assochem.in, marketing@assochem.in, mail@assochem.in

Support